A Guide to Recirculation Aquaculture - Part 2

Chapter 2: The recirculation system step by step

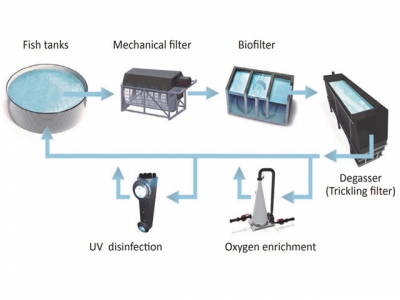

Figure 2.1 Principle drawing of a recirculation system. The basic water treatment system consists of mechanical filtration, biological treatment and aeration/ stripping. Further installations, such as oxygen enrichment or UV disinfection, can be added depending on the requirements.

In a recirculation system it is necessary to treat the water continuously to remove the waste products excreted by the fish, and to add oxygen to keep the fish alive and well. A recirculation system is in fact quite simple. From the outlet of the fish tanks the water flows to a mechanical filter and further on to a biological filter before it is aerated and stripped of carbon dioxide and returned to the fish tanks. This is the basic principle of recirculation.

Several other facilities can be added, such as oxygenation with pure oxygen, ultraviolet light or ozone disinfection, automatic pH regulation, heat exchanging, denitrification, etc. depending on the exact requirements.

Fish in a fish farm require feeding several times a day. The feed is eaten and digested by the fish and is used in the fish metabolism supplying energy and nourishment for growth and other physiological processes. Oxygen (O2 ) enters through the gills, and is needed to produce energy and to break down protein, whereby carbon dioxide (CO2 ) and ammonia (NH3 ) are produced as waste products. Undigested feed is excreted into the water as faeces, termed suspended solids (SS) and organic matter. Carbon dioxide and ammonia are excreted from the gills into the water. Thus fish consume oxygen and feed, and as a result the water in the system is polluted with faeces, carbon dioxide and ammonia.

Figure 2.2 Eating feed and using oxygen results in fish growth and excretion of waste products, such as carbon dioxide, ammonia and faeces.

Only dry feed can be recommended for use in a recirculation system. The use of trash fish in any form must be avoided as it will pollute the system heavily and infection with diseases is very likely. The use of dry feed is safe and also has the advantage of being designed to meet the exact biological needs of the fish. Dry feed is delivered in different pellet sizes suitable for any fish stage, and the ingredients in dry fish feed can be combined to develop special feeds for fry, brood stock, grow-out, etc.

In a recirculation system, a high utilization rate of the feed is beneficial as this will minimise the amount of excretion products thus lowering the impact on the water treatment system. In a professionally managed system, all the feed added will be eaten keeping the amount of uneaten feed to a minimum. The feed conversion rate (FCR), describing how many kilos of feed you use for every kilo of fish you produce, is improved, and the farmer gets a higher production yield and a lower impact on the filter system. Uneaten feed is a waste of money and results in an unnecessary load on the filter system. It should be noted that feeds especially suitable for use in recirculation systems are available. The composition of such feeds aims at maximising the uptake of protein in the fish thus minimising the excretion of ammonia into the water.

The environment in the fish rearing tank must meet the needs of the fish, both in respect of water quality and tank design. Choosing the right tank design, such as size and shape, water depth, self-cleaning ability, etc. can have a considerable impact on the performance of the species reared.

If the fish is bottom dwelling, the need for tank surface area is most important, and the depth of water and the speed of the water current can be lowered (turbot, sole or other flatfish), whereas pelagic living species such as salmonids will benefit from larger water volumes and show improved performance at higher speeds of water.

In a circular tank, or in a square tank with cut corners, the water moves in a circular pattern making the whole water column of the tank move around the centre. The organic particles have a relatively short residence time of a few minutes, depending on tank size, due to this hydraulic pattern that gives a selfcleaning effect. A vertical inlet with horizontal adjustment is an efficient way of controlling the current in such tanks. In a raceway the hydraulics have no positive effect on the removal of the particles. On the other hand, if a fish tank is stocked efficiently with fish, the self-cleaning effect of the tank design will depend more on the fish activity than on the tank design. The inclination of the tank bottom has little or no influence on the self-cleaning effect, but it will make complete draining easier when the tank is emptied.

Figure 2.5 An example of octagonal tank design in a recirculation system saving space yet achieving the good hydraulic effects of the circular tank. Source: AKVA group.

Circular tanks take up more space compared to raceways, which adds to the cost of constructing a building. By cutting off the corners of a square tank an octagonal tank design appears, which will give better space utilization than circular tanks, and at the same time the positive hydraulic effects of the circular tank are achieved (see figure 2.5). It is important to note that construction of large tanks will always favour the circular tank as this is the strongest design and the cheapest way of making a tank.

A hybrid tank type between the circular tank and the raceway called a “D-ended raceway” also combines the self-cleaning effect of the circular tank with the efficient space utilization of the raceway. However, in practice this type of tank is seldom used, presumably because the installation of the tank requires extra work and new routines in management.

Sufficient oxygen levels for fish welfare are important in fish farming and are usually kept high by increasing the oxygen level in the inlet water to the tank.

Figure 2.6 Circular tank, D-ended raceway, and raceway type.

Direct injection of pure oxygen in the tank by the use of diffusers can also be used, but the efficiency is lower and more costly.

Control and regulation of oxygen levels in circular tanks or similar is relatively easy because the water column is constantly mixed making the oxygen content almost the same anywhere in the tank. This means that it is quite easy to keep the desired oxygen level in the tank. An oxygen probe placed near the tank outlet will give a good indication of the oxygen available. The time it takes for the probe to register the effect of oxygen being added to a circular tank will be relatively short. The probe must not be placed close to where pure oxygen is injected or where oxygen rich water is fed. In a raceway,

However, the oxygen content will always be higher at the inlet and lower at the outlet, which also gives a different environment depending on where each fish is swimming. The oxygen probe for measuring the oxygen content of the water should always be placed in the area with the lowest oxygen content, which is near the outlet. This downstream oxygen gradient will make the regulation of oxygen more difficult as the time lag from adjusting the oxygen up or down at the inlet to the time this is measured at the outlet can be up to an hour. This situation may cause the oxygen to go up and down all the time instead of fluctuating around the selected level. Installation of modern oxygen control systems using algorithms and time constants will however prevent these unwanted fluctuations.

Tank outlets must be constructed for optimal removal of waste particles, and fitted with screens with suitable mesh sizes. Also, it must be easy to collect dead fish during the daily work routines.

Tanks are often fitted with sensors for water level, oxygen content and temperature for having complete control of the farm. It should also be considered to install diffusers for supplying oxygen directly into each tank in case of an emergency situation.

Figure 2.7 Drumfilter. Source: CM Aqua.

Có thể bạn quan tâm

Phần mềm

Phối trộn thức ăn chăn nuôi

Pha dung dịch thủy canh

Định mức cho tôm ăn

Phối trộn phân bón NPK

Xác định tỷ lệ tôm sống

Chuyển đổi đơn vị phân bón

Xác định công suất sục khí

Chuyển đổi đơn vị tôm

Tính diện tích nhà kính

Tính thể tích ao hồ

A Guide to Recirculation Aquaculture - Part 3

A Guide to Recirculation Aquaculture - Part 3  A Guide to Recirculation Aquaculture - Part 1

A Guide to Recirculation Aquaculture - Part 1