Building a better shrimp nursery, part 1

Benefits and design considerations for these important production tools

Shrimp nursery systems are valuable production tools. Properly designed and implemented, they are high-biosecurity facilities to grow postlarvae (PL) at high densities, from about 2 mg to sizes as large as 3 grams, resulting in healthy, strong and uniform juveniles with significant potential for compensatory growth after their transfer for final grow-out to market size.

Shrimp juveniles reared through nurseries before stocking into growout ponds are stronger, grow faster and typically have better FCR and survival rates, as well as significant potential for compensatory growth.

In this three-part article, adapted from an original publication last year (AQUA CULTURE Asia Pacific March/April 2016, and May/June 2016), we will first discuss basic design considerations. Parts 2 and 3 will discuss water quality, biofloc technology, and feeds and feed management for these nursery systems.

Hyper-intensive nursery systems for juvenile shrimp production have been used for many years and with varying degrees of success. In the early years, nurseries were simple, smaller, earthen ponds by or inside a much larger grow-out pond. In recent years, nursery systems have become much more sophisticated and are recognized as a valuable production tool and a significant opportunity for the shrimp farming industry to increase efficiency and profits, and in some cases to help manage some diseases.

System design and management have also improved and evolved into a consistent, low-risk “factory model” defined by foreseeable production inputs and predictable and stable operating results. There is limited information available on standard design and management of these systems – and there is much variability among systems in use – but many companies are achieving significant success using nurseries as part of their production strategy.

System design and management have also improved and evolved into a consistent, low-risk “factory model” defined by foreseeable production inputs and predictable and stable operating results.

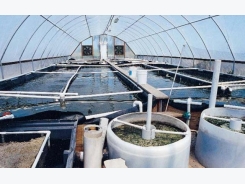

Many shrimp farmers in Latin America are using nurseries as part of their overall production strategy, particularly the larger, older and more integrated companies. Nursery systems are relatively less common in Asia but are quickly expanding and gaining popularity. In general, nurseries typically use plastic-lined tanks or raceways covered by plastic greenhouses or roofs suspended by cables, with an area of 300-7500 m2. Systems can be square or round (typically with circular flow around a central drain) or rectangular (with continuous, rotating water current around a central baffle). Stocking densities range from 500 to 10,000 PL/m3, with individual sizes of 0.3-3g at harvest, and harvest biomasses of 1-3 kg/m3.

Shrimp nursery systems are valuable production tools that can increase efficiency and production, and can provide an important opportunity to increase profits.

Benefits of nursery systems

Nursery systems provide many important benefits. In general, they permit better and more precise management manipulation of the young shrimp within practical and advantageous economic boundaries, which may not be economically practical in larger pond systems.

One important, specific benefit is increased operational control and biosecurity. By reducing the culture area and volume into a series of intensively-stocked and managed tanks/raceways, a significantly higher degree of control is possible over several environmental parameters, water quality, and feeds and feeding, resulting in greater economic efficiencies.

Also, managing smaller unit areas/volumes improves the ability to exclude pathogens, predators and competitors through mechanical, chemical and/or biological filtration. And estimating the juvenile populations and controlling grow-out stocking mortality more accuracy is possible, providing important advantages in managing feed during the pond production phase.

Another important benefit of a two- to three-stage production system using a one- to two-phase nursery is that it permits increasing biosecurity in the quarantined nursery areas. This usually results in higher overall survival rates and production per unit area than in single-phase grow-out systems.

Improved health and disease management is another advantage of nursery systems, because larger, older shrimp will have a more developed immune system. As a management strategy for Early Mortality Syndrome/Acute Hepatopancreatic Necrosis Disease (EMS/AHPND), a nursery phase permits the stocking of large juveniles with better resistance to the disease. And as a management strategy for White Spot Syndrome Virus (WSSV), shrimp in nurseries can be maintained in water temperatures above 30 degrees-C during seasonal times when water temperatures in outdoor ponds are lower and increase the susceptibility of the animals to this disease.

Disease control and diagnostic measures can be more effectively implemented in a properly designed and managed nursery, allowing the grower to monitor and detect infected animals in the nursery before they are transferred to the final, outdoor grow-out ponds. This provides the option of terminating the crop at an earlier stage and restarting the production cycle, thus reducing the financial impact. This is particularly important with the most recent and devastating shrimp diseases, EMS/AHPND, and EHP (caused by the microsporidian Enterocytozoon hepatopenaei), which can be caught early through available and improving histopathology and molecular diagnostic techniques.

Shrimp nursery systems provide shrimp producers with a significant opportunity to increase efficiency and profits

Improved efficiency is another benefit of nurseries. Well managed systems support faster growth and production of bigger and stronger juveniles, with better survival and a significant potential for compensatory growth. Stocking juveniles from nursery systems rather than direct stocking of PL can increase the number of grow-out production cycles (turnovers) by reducing the culture time to market size in the grow-out ponds. This can increase the number of crops per year, allowing a more efficient use of grow-out ponds and significantly improving the farm’s bottom line.

Nursery systems provide many important benefits, including increased operational control and biosecurity, and more precise management manipulation of the young shrimp within practical and advantageous economic boundaries, which may not be economically practical in larger pond systems.

In some regions, indoor nursing systems allow early stocking of PLs during cold seasons and provide an initial advantage in growth. Enclosed intensive nursery systems can further increase the effective stocking window size for seasonal hatchery outputs. This allows greater efficiency for both the hatchery and the farm, and indeed for the entire shrimp farming value-chain.

For farms not integrated with hatcheries, intensive nursery head-start strategies may allow the purchase of seedstock in advance of the peak demand periods, at lower cost and with greater probability and certainty of seedstock delivery. And for shrimp farms in areas of lower salinities, the nursery can also be used as an acclimation system.

Nursery systems also have a few downsides, including greater infrastructure investment (higher construction costs than conventional pond systems) higher operational costs, and increased labor requirements as it requires trained biologists (often to the level of hatchery operators). The technology is much less forgiving of operator and component/equipment mistakes, failures and problems. As stocking densities increase and water exchange decreases, higher organic loads increase the risks to adequate water quality and animal health. And there is increased stress to animals due to more handling and transferring, which can increase susceptibility to several diseases. Therefore, proper management of nursery systems is a critical prerequisite for their success.

Design configurations

The ideal location of a nursery system is in close proximity to, or integrated within the grow-out farm. A critical aspect is ready access to high quality water and appropriate infrastructure. The water source should preferably come from the farm intake canal or before the pump station, to allow draining and dry-out of the main reservoir channel without effecting nursery operations. Water should drain into the farm discharge channel and away from the intake.

To lower costs it is advisable to locate nurseries close to an existing main and emergency backup power source. If possible, it should be near the farm main administration area close to offices, supplies, personal, guards and supervisors. Ideally, construction location should be high enough for good drainage and no more than 5- to 10-minute travel time to the farthest pond in the farm. The size and shape (rectangular, oval, round, stacked shallow raceways) of the nursery system and its tanks are very variable, and it can be a single-phase, two-phase or even multiple-phase design.

Shrimp nurseries can have different shapes and sizes, each with specific benefits and drawbacks.

Single-phase nursery tanks

Single phase tanks are typically designed to stock 2-10 mg PL to produce 100, 200, or 300-mg juveniles. Tanks are typically from 40 to 200-m3 and under greenhouse or shade cloth coverings. Four different tank shapes are typically used: 1) tanks can be rectangular with water inlet(s) opposite water discharge(s); 2. round tanks with a center drain; 3) oval or rectangular raceway configurations with a center wall to support adequate water circulation and to maintain solids in suspension; and 4) stacked, shallow (10-20 cm of water) rectangular raceway systems designed for super-high densities and to maximize space efficiency.

Most of these systems are built out of concrete, wire mesh, wood, plastic, PVC, fiberglass or formed soil with a plastic liner (HDPE or EPDM – non-toxic liner materials must be used) or epoxy coating. Stocking densities range between 8 to 50 PL/L to produce harvest-size juveniles of 0.1-0.3 grams and a final harvest biomass of 1-5 kg/m3.

Rectangular tanks are easy to build, are space-efficient under standard greenhouses, and hatchery technicians readily relate to their management. But they are less efficient at suspended solid and sludge removal and for feed distribution, and can also be more expensive to build and operate.

Views of rectangular shrimp nursery tanks in China (above) and Ecuador (below).

Oval or rectangular raceway tanks have adequate water circulation for keeping solids in suspension, fit well within greenhouses and can be designed/operated to readily remove wastes. But to some extent they can be more difficult to build and manage than other designs. Regarding production, the consistently highest shrimp biomasses have been produced using these systems.

Oval or plug flow “raceways” are typically 33 to 66 meters long by 5 to 9 meters wide, and depths of 0.7 to 1.2 meters. While they fit nicely into commercial greenhouses and into the conventional free span of hard structures, they require more energy in generating the water flow necessary to deliver their solid waste to their designated removal points.

Shrimp nursery designs should consider the factory model, which uses well-defined inputs that result in steady-state operations with constant production

Oval raceways are really circular tanks that have been compressed on opposite sides, and are better able to fit into a rectangular space such as a commercial greenhouse. To maintain an organized flow, the oval raceway is usually divided down the middle by a center wall. In oval (and rectangular) raceways there can be two drains and two points to pick up solid waste.

Views of round nursery tanks, including outdoor covered units in Ecuador (above), built with a frame and plastic liner; and concrete, uncovered units in Brazil (below).

Round tanks are generally less expensive, easier to build, and have good water circulation for feed distribution and sludge removal (self-cleaning). They are less space (footprint)-efficient and can require large, unique covers and support structures to house them. Many nurseries use round tanks made of fiberglass, concrete, or the most locally cost-efficient materials. However, there are physical size limits to circular systems, as round tanks larger than about 40 meters in diameter lose some of their most desirable characteristics. As the diameter increases, more energy is spent maintaining flow velocities to scour and entrain solid waste, and the tanks can be less effective in channeling solid wastes and sludge to the collection points.

Stacked shallow raceways can maximize the biomass per square-meter footprint (up to 10 times that of other systems), and are unmatched at efficiency to control temperature, feeding and personnel inputs. They are ideal for extreme environments where space and temperature are limitations. These systems are relatively new innovations with initial production results from some promising prototypes suggesting potential for very high production rates. As these systems are commercialized they will have the potential to become much more common, supporting hyper-intensive grow-out operations and inland shrimp farming in cold environments.

Second phase nursery tanks

These are very like the single-phase systems but built at a larger scale. Stocking is usually of 0.1-0.3g juveniles transferred from the first-phase system. Having a second phase nursery at the farm level is related to stocking a greater number of larger juvenile shrimp into production ponds than would be possible from a single-phase system. This strategy is usually beneficial where crops are seasonal and where the first farms harvesting get higher prices, and/or to increase rotation (number of crops/year). These systems are typically built in three, differently shaped, covered tanks or ponds (rounded center drain, oval and rectangle), with an average size ranging from 300 to 7500 m3. Stocking from first phase is usually at densities ranging from 0.5 to 5 PL/L to produce juveniles of 1-3 g at harvest and a final harvest biomass of 1-3 kg/m3.

Authors

CRAIG BROWDY, PH.D.

- Director of Research & Development

- Zeigler Bros., Inc.

- Gardners, PA 17324 USA

PETER VAN WYK, M.A.

- R&D Technical Manager

- Zeigler Bros., Inc.

- Gardners, PA 17324 USA

CHRIS STOCK, M.S.

- Sales Manager – Eastern Hemisphere

- Zeigler Bros., Inc.

- Gardners, PA 17324 USA

- www.zeiglerfeed.com

- chris.stock@zeiglerfeed.com

THOMAS R. ZEIGLER, PH.D.

- Senior Technical Advisor & Past President and Chairman

- Zeigler Bros., Inc.

- Gardners, PA 17324 USA

RAMIR LEE

- Technical Representative – Hatchery Feeds

- Zeigler Bros., Inc.

- Gardners, PA 17324 USA

Diego Flores

- Technical Representative – Hatchery Feeds

- Zeigler Bros., Inc.

- Gardners, PA 17324 USA

Có thể bạn quan tâm

Phần mềm

Phối trộn thức ăn chăn nuôi

Pha dung dịch thủy canh

Định mức cho tôm ăn

Phối trộn phân bón NPK

Xác định tỷ lệ tôm sống

Chuyển đổi đơn vị phân bón

Xác định công suất sục khí

Chuyển đổi đơn vị tôm

Tính diện tích nhà kính

Tính thể tích ao hồ

Culture of giant freshwater prawns in China

Culture of giant freshwater prawns in China  Culture of Penaeus vannamei in Single-Phase & Three-Phase…

Culture of Penaeus vannamei in Single-Phase & Three-Phase…