Insects as an alternative raw material in pig feed

Products obtained from insects have a high proportion of crude protein: 40-44% in the case of the black soldier fly larvae, or up to 60% in the case of black fly larvae or in grasshoppers, and even reaching 70% in the case of silkworms.

Black soldier fly larvae

In the European market, pig diets are traditionally based on corn and barley as energy sources and soybean meal as protein source. Due to several circumstances, including the agricultural production conditions, the need to import, the competition with other uses and even speculation, the cost of these raw materials, both between harvesting campaigns and during them, is very variable and, in many occasions, it can reach prices that jeopardize the profitability of pig production. As a result, in the last decades, alternatives to replace these ingredients, at a stable and competitive price, have been explored, going from an increase in the use of wheat and sorghum, although depending on the price competitiveness in relation to corn price, to the reduction of the soybean meal inclusion rate, moving to the use of other vegetable protein sources such as rapeseed meal or peas. The inclusion of by-products from the cereal industry or the biofuel production is also increasing, although the variability in their chemical composition, their seasonal availability and the shortage of specific nutrients limit their use.

Black soldier fly production

Recently, a debate has begun about the use of insects as an ingredient for animal diets (regulation EC 56/2013), perhaps being partly considered as an exotic option, but they also represent a good source of nutrients, which can be comparable to soybean meal when it comes to protein (Verbeke and col., 2015). Insects grow and reproduce easily, have an efficient feed conversion ratio and can be produced from agricultural or food industry waste, including manure and animal faeces, with the consequent environmental benefits. Besides, their waste can be used as organic compost. As an example, a domestic fly can lay up to 1,000 eggs in one week, from which larvae can be obtained in 72 hours. Čičová and col. (2012) state productions of 44 and 74 gr. of larvae from a manure consumption of 180 to 650 gr.

To date, the most studied species, and at the same time the easier ones to produce at a large scale, are the larvae of the black soldier fly (Hermedia ilucens) or the domestic fly (Musca domestica), the mealworm (Tenebrio molitor) and the silkworm (Bombyx mori), although grasshoppers, crickets and termites have also been tried, though they are more expensive to produce. But the potential is much greater: up to 2,000 insect species are eaten by several human cultures (van Huis, 2016). For animal feeds the product can be sold directly as whole insect meal or as insoluble protein, once the fat has been removed.

Black soldier fly

Detailed revisions of the composition of these ingredients have been published by Rumpold and Schlüter (2013) and Makkar and col. (2014). In general, these products obtained from insects have a high proportion of crude protein: 40-44% (based on dry matter) in the case of black soldier fly larvae, or up to 60% in the case of black fly larvae or grasshoppers, even reaching 70% in the case of silkworms (Table 1). On the other hand, their fat content is variable, between 10 and 25% of ether extract, and it can be very high (up to 43%) in the case of Tenebrio molitor larvae, so a treatment to remove the fat would be advisable. Besides, many of them contain high mineral levels, although in general they are proportionally low in calcium, except the black soldier fly larvae. Another added value which has been mentioned is their potential antimicrobial and immunostimulating effects, still not fully proven, assigned to chitin. On the contrary, one of the problems of their use is related to their digestibility, which can be low considering the chitin skeleton of the insects, as reflected in the tests results showing levels of acid detergent fibre of 6-12% in silk worms or 22% of neutral detergent fibre level in grasshoppers.

Table 1: Chemical composition (% over dry matter) of the most interesting insect meals, from a productive point of view (from Makkar and col., 2014) compared to soybean meal and fish meal (from FEDNA, 2010).

| Ashes | Crude Fat | Crude Protein | Total Lysine | Total Methionine | |

| Musca doméstica(larvae) | 10.1 ± 3.3 | 18.9 ± 5.6 | 50.4 ± 5.3 | 3.07 | 1.11 |

| Hermetia illucens (larvae) | 20.6 ± 6.0 | 26.0 ± 8.3 | 42.1 ± 1.0 | 2.78 | 0.88 |

| Tenebrio mollitor | 3.1 ± 0.9 | 36.1 ± 4.1 | 52.8 ± 4.2 | 2.86 | 0.79 |

| Bombyx mori | 5.8 ± 2.4 | 25.7 ± 9.0 | 60.7 ± 7.0 | 4.25 | 2.12 |

| Soybean meal (44% CP) | 7.0 | 2.2 | 50.0 | 3.05 | 0.67 |

| Fish meal (67% CP) | 16.3 | 10.1 | 71.8 | 5.31 | 1.94 |

Although it is necessary to optimize production conditions to reduce costs, guarantee a constant availability at a reasonable price and define the environmental effect of their production as, so far, insect production is carried out at a small scale, currently there is an increase in insect farms, not only in Asian and African countries, but also in Europe. Also, we must consider the possible initial rejection of the market to animal products fed with insects because of consumers’ prejudices, and we must not forget the potential limitations regarding digestibility, palatability and allergenicity (Verbeke and col., 2105). In any case, the knowledge about these products is still scarce, and much more information is needed regarding the optimal production, composition and digestive use, food safety criteria and product quality, before considering using insects as a viable alternative ingredient.

Có thể bạn quan tâm

Phần mềm

Phối trộn thức ăn chăn nuôi

Pha dung dịch thủy canh

Định mức cho tôm ăn

Phối trộn phân bón NPK

Xác định tỷ lệ tôm sống

Chuyển đổi đơn vị phân bón

Xác định công suất sục khí

Chuyển đổi đơn vị tôm

Tính diện tích nhà kính

Tính thể tích ao hồ

Strategies to control piglet weight variability in the…

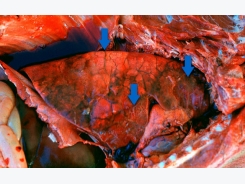

Strategies to control piglet weight variability in the…  Prevention of the disease caused by Actinobacillus pleuropneumoniae

Prevention of the disease caused by Actinobacillus pleuropneumoniae